QH11D系列精密剪板机性能特点:

QH11D系列精密剪板机性能特点:

●相比较传统剪板机外形美观,简洁时尚●剪切精度高●后挡料采用齿条齿轮传动(手动、电动)控制尺寸精准●传动采用电磁吸盘制动,电机与闭合式齿轮箱与轴转动,结构紧凑;可单次、可连续●不剪切时,电机不转动,减少无为的消耗,节约能源●适合薄板加工,APS、PP片板等非金属材料的加工剪切. Performance characteristics of QH11D series precision shearing machine:

Compared with traditional shearing machines, it has a beautiful appearance, simple and fashionable

● High cutting accuracy

The rear gear adopts rack and pinion transmission (manual, electric) to control the size accurately

The transmission adopts electromagnetic suction cup braking, and the motor and closed gearbox rotate with the shaft, with a compact structure; Can be done once or continuously

When not cutting, the motor does not rotate, reducing the consumption of inactivity and saving energy, making it a new generation of energy-saving products

Suitable for thin plate processing, cutting of non-metallic materials such as APS and PP sheets

如何选择更适用的精密剪板机,我们要从多角度入手,机械设备在迁移前,应查明行驶路线上的桥梁、涵洞的上部净空及道路、桥梁的承载能力。通过桥梁时,应采用低速档慢行,在桥面上不得转向或制动。承载能力不够的桥梁,必须事先制定加固措施。 机械设备必须安装在平整、坚实的场地上,遇松软的场地必须先夯实,并加垫基台木和木板。在台架上作业的钻机,钻机底盘与台架必须可靠连接。 机械设备必须安装稳固、周正水平。回转钻机的回转中心、冲击(冲抓)钻机钻架天车滑轮槽缘的铅垂线应对准桩孔位置,偏差不得大于设计允许值(10~15mm)。 必须在机械设备的传动部分(明齿轮、万向轮、皮带和加压轮)的外部安装牢固的防护栏杆或防护罩,加压轮用的钢丝绳必须加防护套。 剪板机有一套电启动系统,手动小型精密剪板机,那么,精密剪板机型号选择,它是怎样操作的呢,有什么样的性能?接下来电动剪板机小编将进行详细的介绍。 剪板机的动力系统一般使用普通异步电机,精密剪板机,在剪板过程中不断启停,能耗大、效率低。针对这些情况,可以对剪板机进行自动化改造,提高工作效率和剪板精度,降低能耗.

如何选择更适用的精密剪板机,我们要从多角度入手,机械设备在迁移前,应查明行驶路线上的桥梁、涵洞的上部净空及道路、桥梁的承载能力。通过桥梁时,应采用低速档慢行,在桥面上不得转向或制动。承载能力不够的桥梁,必须事先制定加固措施。 机械设备必须安装在平整、坚实的场地上,遇松软的场地必须先夯实,并加垫基台木和木板。在台架上作业的钻机,钻机底盘与台架必须可靠连接。 机械设备必须安装稳固、周正水平。回转钻机的回转中心、冲击(冲抓)钻机钻架天车滑轮槽缘的铅垂线应对准桩孔位置,偏差不得大于设计允许值(10~15mm)。 必须在机械设备的传动部分(明齿轮、万向轮、皮带和加压轮)的外部安装牢固的防护栏杆或防护罩,加压轮用的钢丝绳必须加防护套。 剪板机有一套电启动系统,手动小型精密剪板机,那么,精密剪板机型号选择,它是怎样操作的呢,有什么样的性能?接下来电动剪板机小编将进行详细的介绍。 剪板机的动力系统一般使用普通异步电机,精密剪板机,在剪板过程中不断启停,能耗大、效率低。针对这些情况,可以对剪板机进行自动化改造,提高工作效率和剪板精度,降低能耗.

How to choose a more suitable precision shearing machine, we need to start from multiple perspectives. Before relocating the mechanical equipment, we should identify the upper clearance of bridges and culverts on the driving route, as well as the bearing capacity of roads and bridges. When passing over bridges, low-speed gear should be used for slow driving, and turning or braking is not allowed on the bridge deck. Bridges with insufficient load-bearing capacity must be reinforced in advance.

Mechanical equipment must be installed on a flat and solid ground. In case of soft ground, it must be compacted first and cushioned with base wood and wooden boards. The drilling rig operating on the platform must have a reliable connection between the drilling rig chassis and the platform.

Mechanical equipment must be installed stably and horizontally. The rotation center of the rotary drilling rig and the vertical line of the pulley groove edge of the impact (grabbing) drilling rig drilling frame should be aligned with the position of the pile hole, and the deviation should not exceed the design allowable value (10-15mm).

A sturdy protective railing or cover must be installed on the exterior of the transmission parts of the mechanical equipment (open gears, universal wheels, belts, and pressure wheels), and the steel wire rope used for the pressure wheel must be protected with a sleeve.

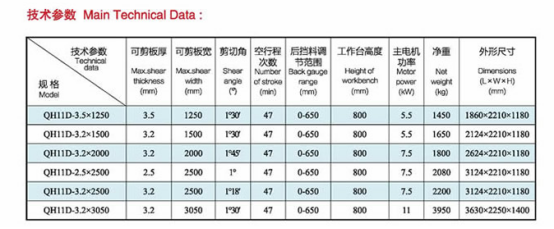

The shearing machine has an electric starting system and a manual small precision shearing machine. So, what is the model selection of the precision shearing machine, how is it operated, and what are its performance? Next, the editor of the electric shearing machine will provide a detailed introduction.

The power system of a shearing machine generally uses ordinary asynchronous motors. Precision shearing machines constantly start and stop during the shearing process, resulting in high energy consumption and low efficiency. In response to these situations, the shearing machine can be automated to improve work efficiency and shearing accuracy, and reduce energy consumption.